The Harver Group

The power of Harver is that we are taking a fresh look at people and organizations. We combine expertise in HR, psychology, assessments and Service & User experience design in a team.

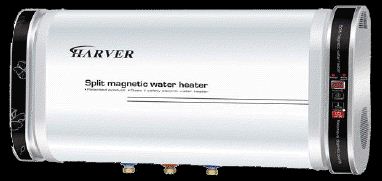

Power Solutions Harver Group Water Heaters

Split magnetic water heater has two parts: storage tank & generator unit

- NCRS Certified

- Factory fitted Temperature/Pressure valve included

- Includes Safety pressure valve

- 15 Amp plug connection

- 3 year warranty on manufacture & material defects

Description

Salient Features

- Split magnetic induction water heating

- High quality insulation

- Stainless steel water storage unit

- Attractive plastic housing material

- Wall mounted installation

- Capacity: 30L, 40L, 50L, 60L

- Power range required : 2000 - 4000w

- Voltage : 220v

- Standard plumbing fitting

- Class 2 safety rating (no transfers of AC to contents)

- 15 Amp plug connection

- No maintenance costsCan be installed at point of use

How it works

Using a magnetic induction process the water is heated more rapidly than conventional water geysers

The electrical supply to the generator in the unit is converted into a magnetic field which heats the water

There is no direct alternating current (AC) in close proximity to the water, which makes the unit safe

The unit uses new temperature sensing technology that is more accurate

The unit includes a high density thermal insulation layer, to sustain the water temperature

Technical Aspects

The unit has a Class 2 safety rating, the first of its kind in the word, primarily because there is NO transfer of alternating current (AC) into the water or the holding tank

The risk of rupture of the geyser is eliminated as a built in temperature - pressure valve forms part of the unit (factory installed)

The electrical configuration of the unit is such that the likelihood of switch leakage malfunction is reduced, as is the buildup of pipe rust & iron content in the water

The unit includes a high density thermal insulation layer around the storage tank, which is made stainless steel and magnesium for increased product life

The geyser draws between 2kw - 4kw of power depending on the size of the geyser

Electricity Usage

To heat a conventional150lt geyser from 20DegC to 65DegC takes two and a half hours and uses 7.8kw of electricity

To heat the same amount of water via the Harver induction water heater will take approximately 1 hour and uses approximately 2.5kw of electricity

Operating cost Approximately 1/3 of the cost of a conventional geyser

Substantial water saving due to location of the unit